Tests

Yesterday the strength was of the printed rings, with and without fibers. First we tried 4 rings: 4 x 6mm PLA, 4 x 6mm PLA with kevlar fibers, and 5 x 6mm PLA, and 5 x 6 mm PLA with fibers. These were attached to the tensile testing with a rope.

These are the 4×6 mm rings.

These are the 5×6 mm rings.

The tests are repeated with the same sort of rings to eliminated the small differences in quality.

For the next bars we tried a bending-test. The 8 x 4 x 100mm PLA bars with fiber and without are used. The black bar is also made of PLA, but the white roll was finished.

These are the bars of 8×4 mm; The black bar is also PLA but only a different color.

Set up of the 3 point bending-test.

Results

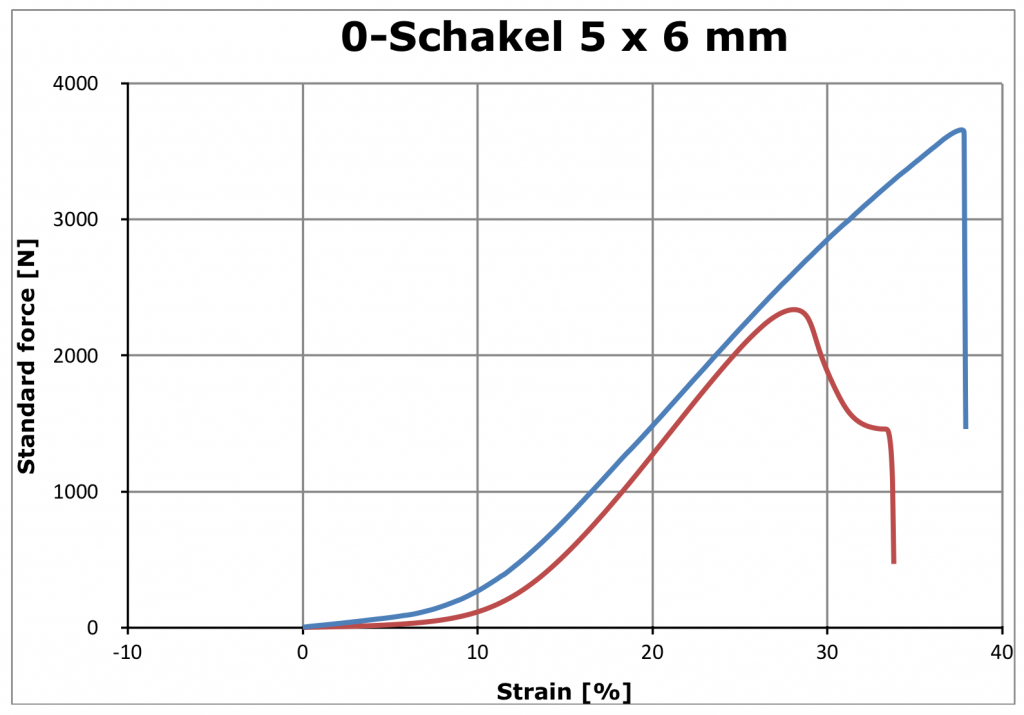

The results of the strength of the chain link (5 x 6 mm) were very promising. The one without fibers snapped at a force of 2337 Newton, which is about 258 kilograms. The one with the kevlar fibers broke at 3659 Newton, or 373 kilograms. This makes the link with fibers about 1.6 times stronger.

The red line is from the print without fibers, the blue one is with fibers.

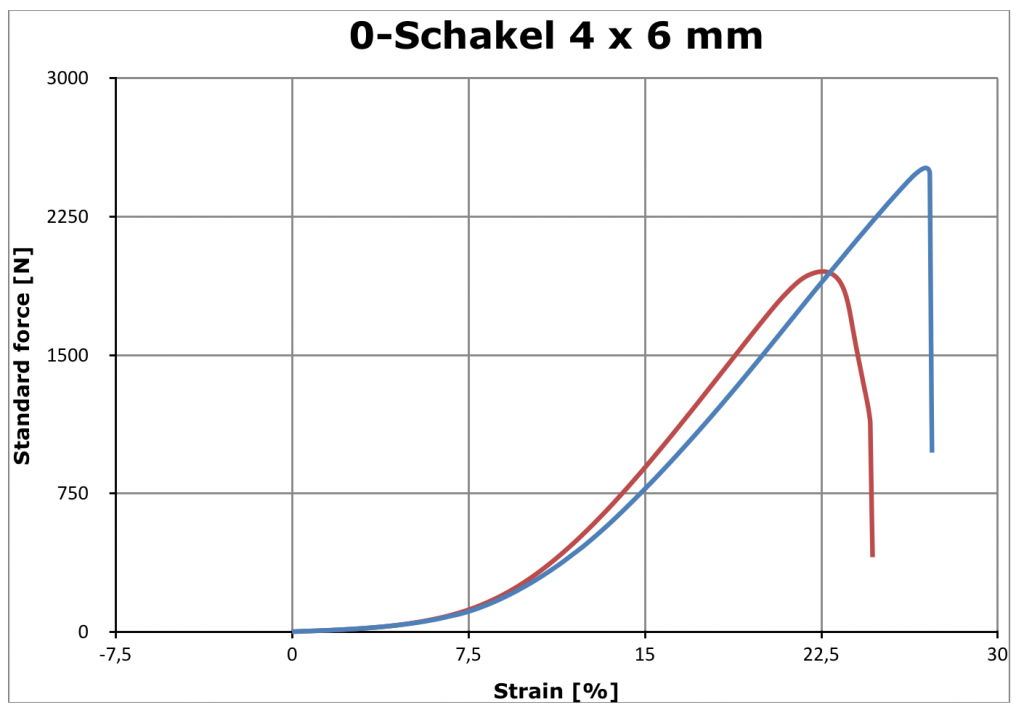

Almost the same results came from the test of the other chain link (4 x 6 mm). The one with fibers is also significantly stronger. Without the fibers, it snapped at a force of 1952 Newton, which is about 199 kilograms. The link with the kevlar fibers broke at 2513 Newton, or 256 kilograms. This makes the link with fibers about 1.3 times stronger.

The red line is from the one without fibers; the blue one is from the link with fibers.

As you can see in both graphs the fibers suddenly snap. The PLA has more strain after the strongest point. The results of the Bending-test are coming soon.

In the video below you can see one of the PLA test prints being ripped apart in slow motion.

[youtube]https://www.youtube.com/watch?v=DkZEHcvoXqw[/youtube]